The Hamilton Health Sciences Experience

by Gwen Liu, R.Ph, B.Sc.Phm, PharmD, ACPR

The National Association of Pharmacy Regulatory Authorities (NAPRA) standards highlight the importance of a quality assurance program when performing sterile compounding tasks. The intent of such a program is to generate information demonstrating that the compounding pharmacy’s personnel, facilities and equipment (i.e. hoods) attain and maintain the conditions required for contamination-free compounding of sterile preparations. A key component of the quality assurance program is environmental verification of the parameters required by facilities according to the NAPRA standards.

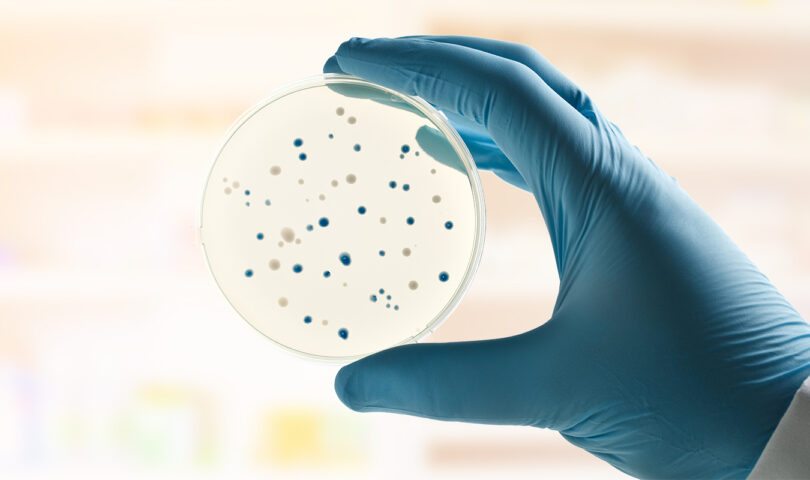

In addition to temperature, humidity and pressure differential monitoring, pharmacies are now required to test for viable, non-viable air and surface sampling in controlled areas of the cleanrooms and the primary engineering control (hood) to ensure they fall within NAPRA requirements for ISO air classification and number of colony forming units.

Several years ago at Hamilton Health Sciences (HHS), the Pharmacy department began the creation of an environmental monitoring program to test for air and surface particle counts, as well as conducted gloved fingertip and media fill testing to meet the new NAPRA standards. The following is a step-by-step description of considerations into how HHS implemented their program.

VIABLE, NON-VIABLE AND AIR SURFACE SAMPLING

Step 1: Obtain organizational support

Having the support of upper management is important before setting up an environmental monitoring program. Many hospital cleanroom facilities may not be NAPRA compliant and need renovation. The organization must be cognizant that once testing begins, their current cleanroom facilities may yield particle count levels beyond acceptable range, otherwise known as particle count excusions.

Step 2: Set up a working group with key stakeholders

The working group should include representation from pharmacy operations, facilities, occupational health/health and safety, housekeeping, microbiology and infection control. Educating the group on the NAPRA requirements for cleanroom facilities is vital to ensure everyone is clear and aware of the expectations. Deciding whether to in-source or outsource to a third party vendor is the next decision. Most hospitals will likely outsource since most organizations will not have in-house expertise. Assessment of third party certifier competency should include a discussion of their knowledge of the required cleanroom standards; the type of equipment being used to test; and the testing parameters that certifiers must follow. This information is listed in the NAPRA standards.

Step 3: Design a policy and a sampling plan

The first step is to obtain a floorplan of the cleanroom facility area. The designated certifier, together with review from the working group should identify areas in the cleanroom to be tested. Typical areas targeted for non-viable and viable air sampling are inside the hoods and certain areas in the cleanroom and anteroom (i.e. centre of the room and doorways). Counters, inside hoods, and high touch areas are some areas to consider for surface sampling. As well, all air and surface viable samples must be identified to the genus level. There are specific accreditation standards that labs are required to meet in order to demonstrate that they have the expertise to process environmental samples. It is important to be mindful that speciating samples and the total number of samples taken can have a significant impact on the budget.

Step 4: Design an action plan to address excursions

The different members of the working group will be critical in addressing excursions discovered once monitoring is in place. The initial testing will yield some expected and possibly unexpected results. Developing an action plan to manage excursions in each area will be helpful when such results are obtained. A hood shutdown will have a strong impact on daily operations. Thus, discussing the action plan for an excursion finding in the hood and identifying the parameters as to when the hood would be required to be shut down is important.

Step 5: Identify equipment required

Purchase of equipment and testing materials (i.e. agar plates), will not be required if the testing is outsourced to a third party certifier. Some sites may consider purchasing a particle count tester if additional, more frequent testing is desired.

Step 6: Implement testing

Testing should be performed in dynamic conditions when staff are in the room performing their daily activities in the cleanroom. The certifier must follow the same procedures that sterile compounding staff must follow for donning/doffing personal protective equipment and hand hygiene. They should also wipe down all equipment with sterile 70% isopropyl alcohol before bringing it into the cleanroom space. After surface sampling, a designated person to wipe the residue from the agar plates should be identified.

Step 7: Review results and address excursions

As each testing session occurs, patterns may emerge that may prompt review of regular procedures (i.e. cleaning). Facilities/engineering staff will be helpful in addressing ventilation issues (i.e. pressure differential, airflow, hood performance). Housekeeping and infection control will assist in addressing and recommending cleaning practices (i.e. focused cleaning in particular areas, cleaning agents). Viable air and surface results may also guide decisions surrounding cleaning procedures in the cleanroom facilities. Remember to document actions completed when addressing excursions.

GLOVED FINGERTIP AND MEDIA FILL TESTING

Step 1: Set Up a working group

Consulting the hospital’s microbiologist and lab department is beneficial when embarking on development of testing protocols. Their expertise in microbiology and lab standards and procedures is valuable to the process. At HHS, the regional microbiology lab agreed to process the gloved fingertip agar plates for the pharmacy. Media fill testing is completed and incubated in the pharmacy department/lab depending on the site.

Step 2: Develop a policy and procedure for testing and a failed result action plan

Developing a policy outlining the details of the gloved fingertip and media fill testing is important. The policy shall include purpose, frequency of testing, detailed step-by-step testing procedure, incubation temperatures and duration, actionable levels and plan. The media fill test procedure should be reflective of the most challenging sterile compounding procedures and ideally completed at the end of a shift/day. Designing a detailed action plan to address positive results is important before starting so that there is a clear plan to address positive results and to educate staff on the process of handling a positive result.

Step 3: Identify equipment required

In most instances, an incubator will be required. If purchase of an incubator is required, the hospital’s microbiology lab may have some insight and recommendation into reputable vendors. Ideally, the location of the incubator should be in a separate area away from medication storage, food and drink. Daily documentation of incubator temperatures is a requirement. As well, the lab may have existing contracts with vendors they can recommend that can supply agar plates and tryptic soy broth media. The use of agar paddles sold by certain vendors are not recommended since the agar is too thin compared to the thickness of the agar in plates.

Step 4: Educate sterile compounding staff on new testing requirements

Educating sterile compounding staff on the new testing procedures and the rationale behind testing can help alleviate anxiety around these new testing requirements.

Step 5: Implement testing

Scheduling testing for each sterile compounding staff member will require coordination of arrival of testing materials and scheduling time in the staff’s shift. Depending on the resources and number of staff required for testing, scheduling the testing in a focused time frame may be easier or staggering the testing throughout the year may make more sense.

CONCLUSION

At HHS, developing and implementing an environmental monitoring program has been an informative and enlightening experience. It has highlighted the importance of having standard operating procedures for cleaning, donning/doffing of personal protective equipment, hand hygiene, and proper aseptic technique, as well as proper facility layout and ventilation design in order to maintain a state of control in a cleanroom facility. Following the steps outlined above will help your institution develop and implement an environmental monitoring quality assurance program for your cleanroom that will help meet the NAPRA standards.